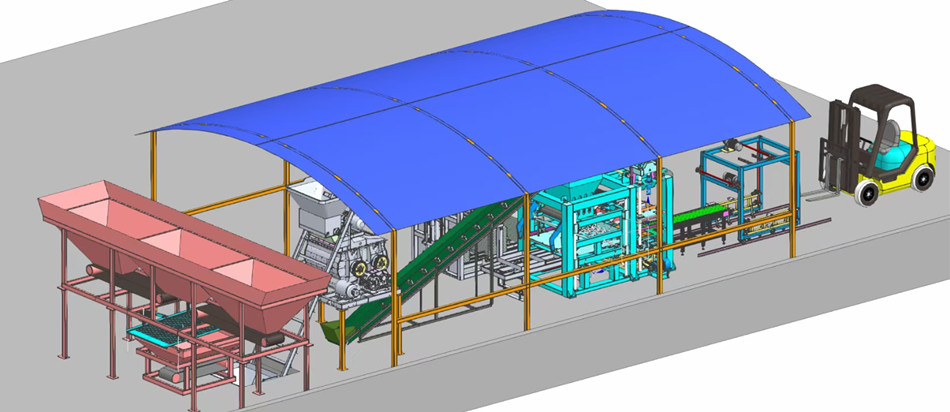

Introduction of QT10-15 hydraulic automatic complete cement block production plant:

| Item No. | Name | Function |

| A | PLD1200 3 hoppers batching machine | Wheelloader load materials, PLD1200 weight materials as per set scale |

| B | JS750 Double Shaft Forced Mixer | Mixing cement, sand, stone powder, flyash…. produce concrete |

| C | Belt Conveyor (8m) | Transfer concrete to block machine material hopper |

| D | QT10-15 Automatic Hydraulic Block Machine | Produce concrete blocks bricks automatically |

| E | Hydraulic Station (18.5kw;04 valve) | Supply hydraulic pressure to oil cylinders of block machine |

| F | Automatic PLC Control Box | Control block machine work automatically |

| M | Color Feeder Machine (Optional) | Put color face on surface of paving bricks |

| N | Pallet feeding machine | Bulk pallets feeding into block machine pallet box automatically |

| G | Block Receiver | Delivery out fresh blocks bricks from block machine to stacker |

| H | Stacker | movable 2 pallets stacker (stacking fresh blocks automatically) |

Technical Information of QT10-15 Automatic hollow blocks moulding machine:

| Model No. | QT10-15 |

| Forming Cycle | 12-15 Second |

| Vibration Frequency |

4800-5200r/min |

| Vibration Force |

80-100KN |

| Pressure | 18-21Mpa |

| Pallet Size | 1100-870-25/30mm |

| Total Power | 92.6KW (Hydraulic Station motor 18.5kw; Vibration Motor 11kw) |

| Workers | 3-5 workers |

| Workshop Size (Min.) | 28m Length, 4.5m Width, 6m Height |

| Block Machine Size | 5360mm(L)-2850mm(W)-2850mm(H) |

| Host Block Machine Weight | 7600 KGS |

| JS500 Mixer Capacity |

23-28cbm/hour (One bag 50kg cement mixing a time) |

| Generator | 200KW |

Production Capacity of QT10-15 Automatic concrete hollow block making machine:

QT10-15 automatic block machine has different production capacity for different sizes of blocks, paver, curbstone, hourdis.

The following production capacities are for some popular sizes of blocks, bricks, hourdis and interlocking pavers.

| Item No. | Block Size | Production Capacity | Block Photo |

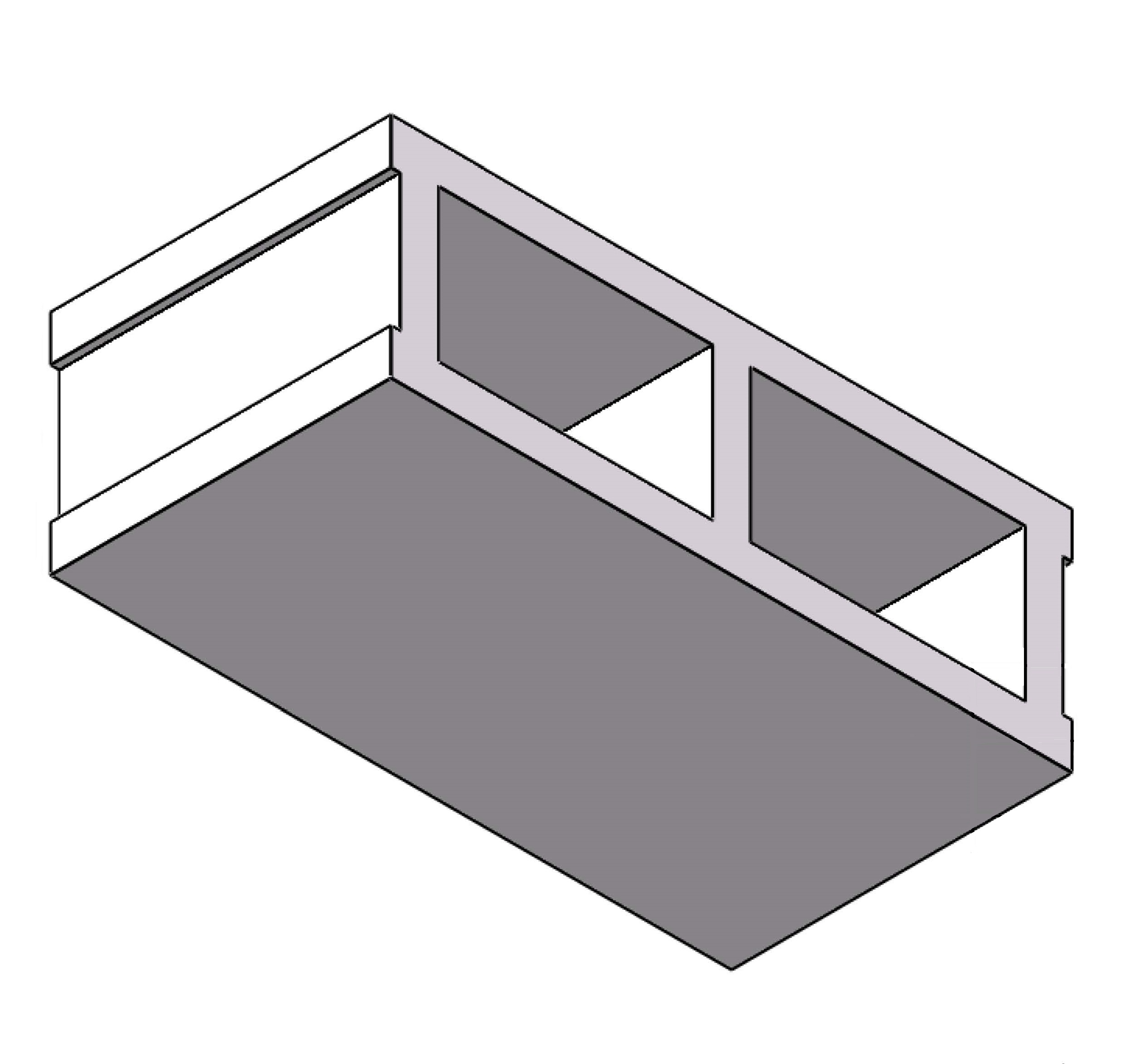

| 1 | Hollow/Solid Block

400-200-200mm (8 inch) |

10 blocks in a mold

2400 blocks per hour; 19200 blocks per 8 hours |

|

| 2 | Hollow/Solid Block

400-150-200mm (6 inch) |

12 blocks in a mold

2880 blocks per hour; 23040 blocks per 8 hours |

|

| 3 | Hollow/Solid Block

400-125-200mm (5 inch) |

14 blocks in a mold

3360 blocks per hour; 26880 blocks per 8 hours |

|

| 4 | Hollow/Solid Block

400-100-200mm (4 inch) |

18 blocks in a mold

4320 blocks per hour; 34560 blocks per 8 hours |

|

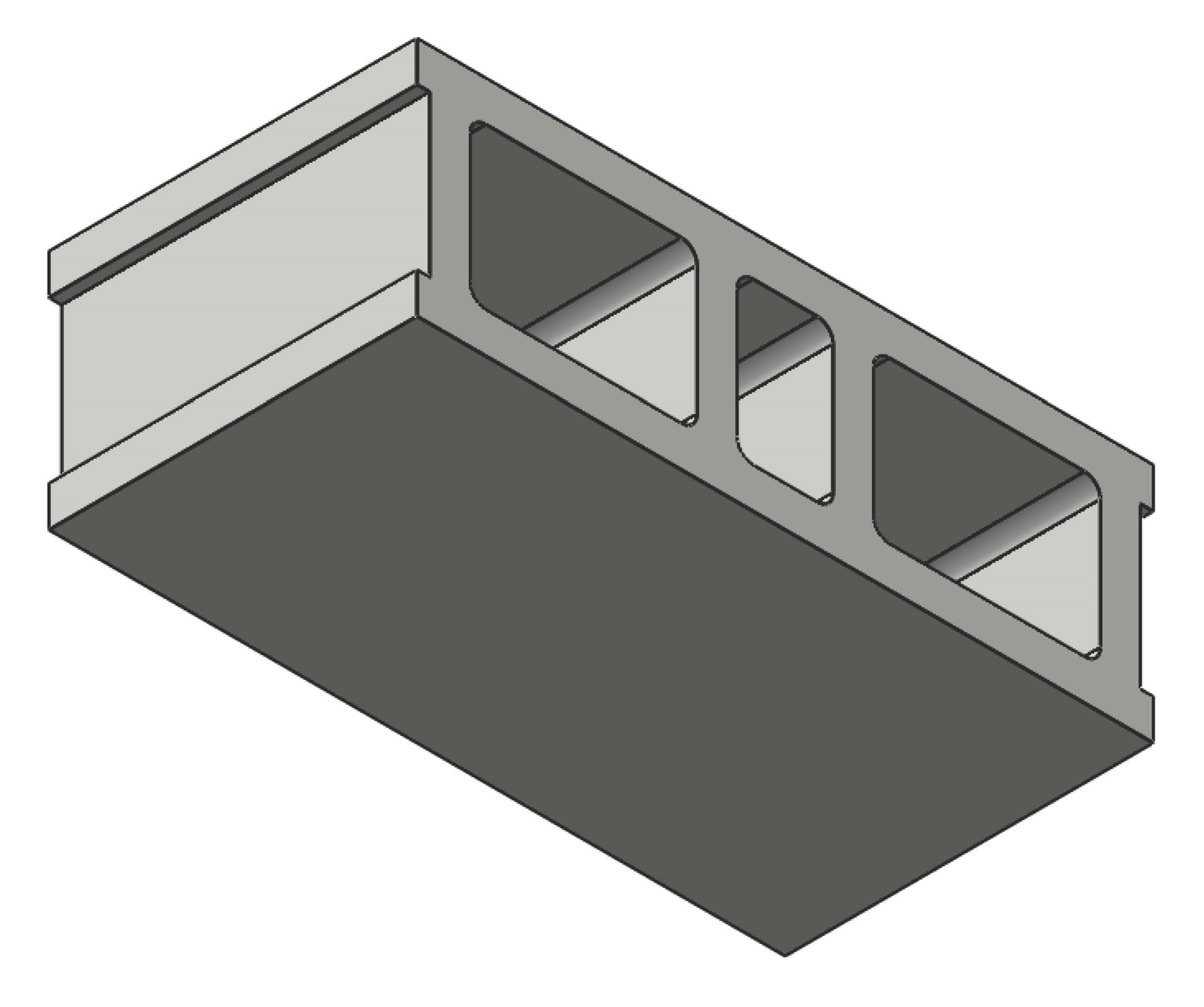

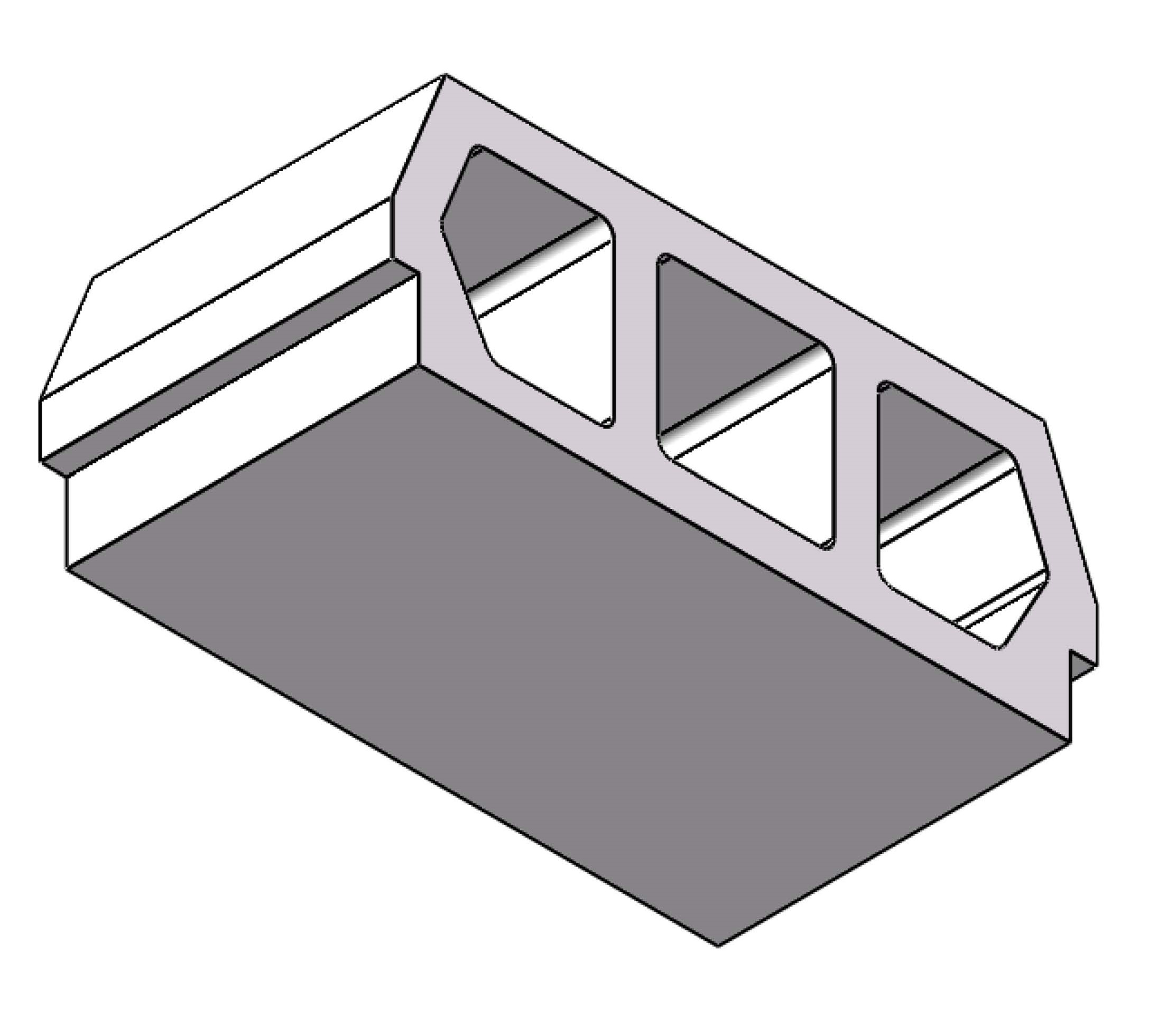

| 5 | Hourdis

500-150-200mm |

8 blocks in a mold

1920 blocks per hour; 15360 blocks per 8 hours |

|

| 6 | Zig Zag Paver

225-112.5-60/80mm |

24 blocks in a mold

5760 blocks per hour; 46080 blocks per 8 hours |

|

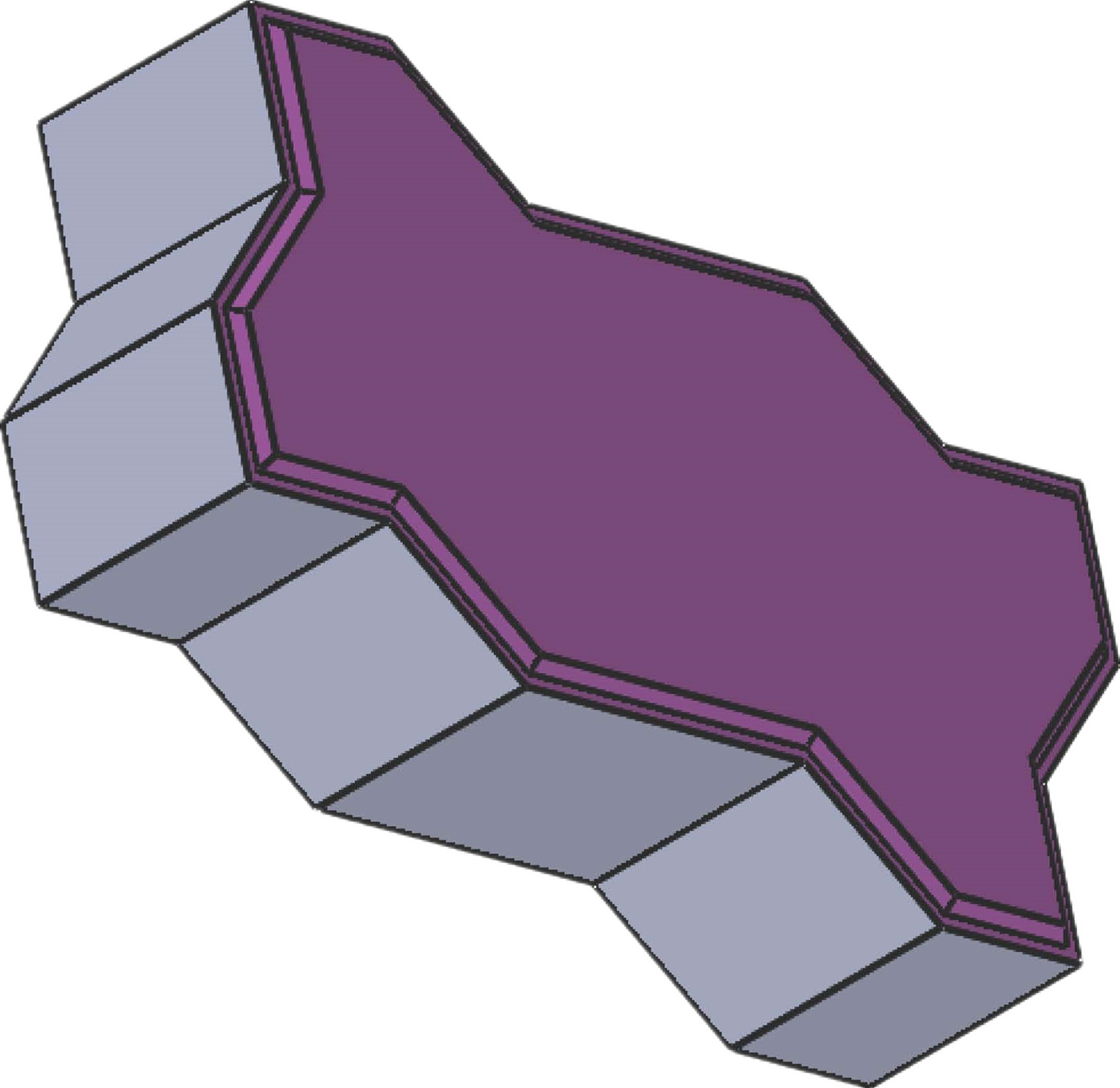

| 7 | Interlocking Paver

200-165-60/80mm |

18 blocks in a mold

4320 blocks per hour; 34560 blocks per 8 hours |

|

| 8 | Rectangle Paver

200-100-60/80mm |

27 blocks in a mold

6480 blocks per hour; 51840 blocks per 8 hours |

|

| 9 | Square Paver

250-60/80mm |

6 blocks in a mold

1440 blocks per hour; 11520 blocks per 8 hours |

|

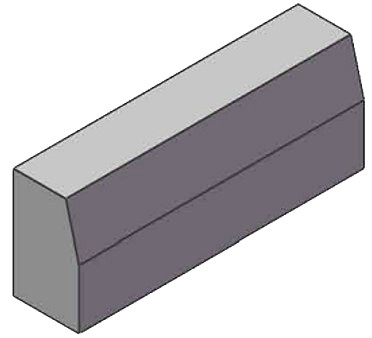

| 10 | Curb Stone

500-150-250mm |

6 blocks in a mold

1440 blocks per hour; 11520 blocks per 8 hours |

|

Design of blocks, interlocking paving bricks, curbstones for reference: